- Quality Assurance and Certifications

- Cost-Effective Manufacturing with Global Reach

- Flexible and Scalable Production Capabilities

- Dedicated Support and Project Management

- Advanced Engineering and Design Support

- Sustainable and Environmentally Friendly Practices

- Contract Manufacturing Services from Pace Electronics

Optimizing production while maintaining quality and cost-effective processes is increasingly important in the electronics industry. Utilizing comprehensive contract manufacturing services from a trusted provider can help manufacturers by utilizing existing infrastructure, supply chain relationships, and streamlined processes. When combined with specialized expertise and a dedicated client focus, it can also reduce the pressure on in-house operations.

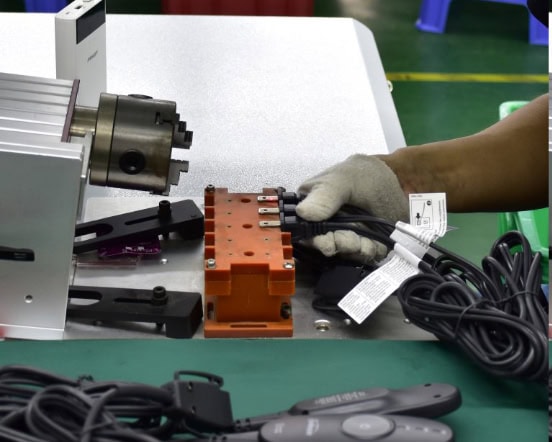

Pace Electronics provides unsurpassed contract manufacturing services for a diverse range of electronic products. With extensive experience and state-of-the-art facilities, we streamline the process from the initial design concept to final assembly and testing. Our knowledgeable staff maintains an unwavering commitment to exceptional quality, ensuring our products meet the highest standards for market success.

Quality Assurance and Certifications

At Pace Electronics, quality assurance is at the forefront of our contract manufacturing services and is a foundational principle in how we serve businesses throughout the electronics industry. We adhere to stringent industry standards and maintain numerous quality certifications as part of our ongoing commitment to excellence.

Our quality management system includes in-process quality controls, incoming material inspections, and stringent final product testing to identify and minimize product defects. The following industry-specific certifications support our dedication to providing superior quality and reliability:

- ISO 9001:2015

- ISO 13485:2016 (medical devices)

These quality certifications align with internationally recognized benchmarks for risk mitigation, quality management, and continuous improvement.

Cost-Effective Manufacturing with Global Reach

Pace Electronics delivers cost-effective contract manufacturing solutions, leveraging our strategic global reach without compromising quality. By optimizing our supply chain logistics and production processes, we can minimize expenses to ensure competitive pricing. Our established global network of manufacturing facilities and suppliers allows us to efficiently manage production by sourcing dependable components, significantly reducing lead times and manufacturing costs.

Thanks to our extensive global footprint, we can provide scalable solutions in high-volume production or small-batch runs that easily adapt to our clients’ specific market demands. This flexibility, combined with our cost-effective strategies, leads to significant savings for our clients.

Partnering with Pace Electronics offers the benefit of global efficiencies as well as the highest level of reliability and quality. From our executive team to our project managers to our factory workers, our employee retention rates are unparalleled. Pace employees are loyal and vested in our clients’ success and possess incomparable industry expertise.

Flexible and Scalable Production Capabilities

Pace Electronics offers scalable, highly flexible production capabilities that seamlessly adapt to our clients’ evolving manufacturing needs. Our cutting-edge facilities respond efficiently to:

At Pace Electronics, we understand that market demands are constantly changing, and our agile approach allows us to quickly adjust our production capacities to meet our clients’ specific requirements without compromising quality or lead times. Our continuous investment in cross-trained personnel and versatile manufacturing equipment ensures we can transition between various production volumes and product types. This unsurpassed adaptability reduces risk while optimizing time-to-market.

Partnering with Pace Electronics provides clients with an experienced contract manufacturing partner that meets specific business needs, providing the necessary flexibility to manage fluctuating demand and capitalize on market opportunities. Our continuing investments in versatile manufacturing equipment and cross-trained personnel ensure that we can seamlessly transition between different product types and production volumes.

Dedicated Support and Project Management

Pace Electronics provides meticulous project management services and unparalleled client support throughout the process, validating our continued commitment to ensuring our clients’ success. From the first consultation through final delivery, our clients can expect personalized service and transparent communication. We assign a dedicated project manager to every project, providing a single point of contact that offers clear updates and seamless coordination through every stage of production to deliver optimal results.

Our project management approach features:

Further, utilizing robust systems to manage changes and track progress allows us to offer exceptional support, keeping clients informed throughout the manufacturing process. E also use any feedback to drive innovation and design production to meet evolving needs.

Advanced Engineering and Design Support

Pace Electronics serves as a dedicated partner for our clients, offering advanced design and engineering support services as part of our unparalleled contract manufacturing solutions. Our experienced team of engineers collaborates with clients from the initial stages of product development, providing crucial insights to optimize designs for manufacturability, performance, and cost efficiency. We can assist with:

Leveraging cutting-edge design and simulation tools, we can identify potential issues before they negatively impact production, saving valuable time and resources. Our expertise spans multiple electronic disciplines, enabling us to contribute to problem-solving and product innovation. With Pace Electronics, our clients gain a collaborative partner committed to optimizing designs for seamless production.

Sustainable and Environmentally Friendly Practices

Pace Electronics maintains an unwavering commitment to eco-friendly and sustainable manufacturing practices, recognizing our responsibility throughout the production process to minimize our ecological footprint throughout the manufacturing process.

We continuously seek innovative methods for:

- Conserving energy

- Adhering to strict environmental regulations

- Implementing efficient processes to eliminate hazardous substances and reduce emissions

- Managing resources responsibly

- Prioritizing the use of eco-friendly materials whenever feasible

- Reducing waste and associated costs

Partnering with Pace Electronics means choosing a contract manufacturer dedicated to environmental stewardship and the utmost efficiency and quality. Our commitment to sustainable and environmentally friendly practices extends to recycling programs and responsible waste disposal, ensuring our manufacturing processes have a positive impact on both the planet and our products.

Contract Manufacturing Services from Pace Electronics

Pace Electronics is a trusted contract manufacturing partner, delivering unsurpassed global sourcing through robust supply chain management and premier suppliers to simplify operations and produce reliable electronics components. We have customer relationships that have lasted more than 30 years, leveraging cross-industry expertise, dedicated teams, and scalable capabilities to help them move through projects seamlessly while lowering costs and maintaining consistent quality.

Contact us today to learn more about our electronic contract manufacturing services and see how Pace Electronics can meet the specific requirements of your next application.