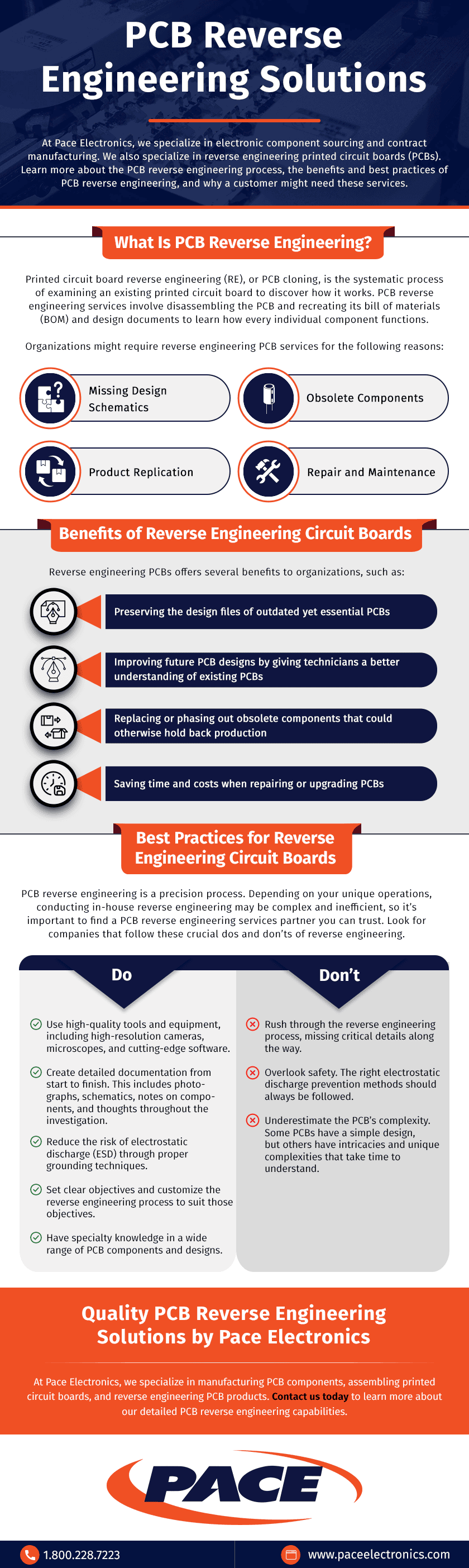

At Pace Electronics, we specialize in electronic component sourcing and contract manufacturing. We also specialize in reverse engineering printed circuit boards (PCBs). Learn more about the PCB reverse engineering process, the benefits and best practices of PCB reverse engineering, and why a customer might need these services.

What Is PCB Reverse Engineering?

Printed circuit board reverse engineering (RE), or PCB cloning, is the systematic process of examining an existing printed circuit board to discover how it works. PCB reverse engineering services involve disassembling the PCB and recreating its bill of materials (BOM) and design documents to learn how every individual component functions.

Organizations might require reverse engineering PCB services for the following reasons:

- Missing design schematics: If a customer has a physical PCB but has lost its original design schematics or supporting documentation, PCB RE solutions can recreate it.

- Obsolete components: Individual components within the PCB may become obsolete and difficult to source, which could delay production of the whole board. With reverse engineering, engineers can identify suitable replacements for the obsolete components.

- Product replication: Reverse engineering can also be used to understand how competitors have built their PCBs. The research can help organizations develop more cost-effective or streamlined versions of those PCB designs.

- Repair and maintenance: By understanding a PCB’s functionality and layout, customers can identify and repair potential malfunctions more easily.

Benefits of Reverse Engineering Circuit Boards

Reverse engineering PCBs offers several benefits to organizations, such as:

- Preserving the design files of outdated yet essential PCBs

- Improving future PCB designs by giving technicians a better understanding of existing PCBs

- Replacing or phasing out obsolete components that could otherwise hold back production

- Saving time and costs when repairing or upgrading PCBs

Best Practices for Reverse Engineering Circuit Boards

PCB reverse engineering is a precision process. Depending on your unique operations, conducting in-house reverse engineering may be complex and inefficient, so it’s important to find a PCB reverse engineering services partner you can trust. Look for companies that follow these crucial dos and don’ts of reverse engineering.

Do:

- Use high-quality tools and equipment, including high-resolution cameras, microscopes, and cutting-edge software.

- Create detailed documentation from start to finish. This includes photographs, schematics, notes on components, and thoughts throughout the investigation.

- Reduce the risk of electrostatic discharge (ESD) through proper grounding techniques.

- Set clear objectives and customize the reverse engineering process to suit those objectives.

- Have specialty knowledge in a wide range of PCB components and designs.

Don’t:

- Rush through the reverse engineering process, missing critical details along the way.

- Overlook safety. The right electrostatic discharge prevention methods should always be followed.

- Underestimate the PCB’s complexity. Some PCBs have a simple design, but others have intricacies and unique complexities that take time to understand.

Quality PCB Reverse Engineering Solutions by Pace Electronics

At Pace Electronics, we specialize in manufacturing PCB components, assembling printed circuit boards, and reverse engineering PCB products. Contact us today to learn more about our detailed PCB reverse engineering capabilities.